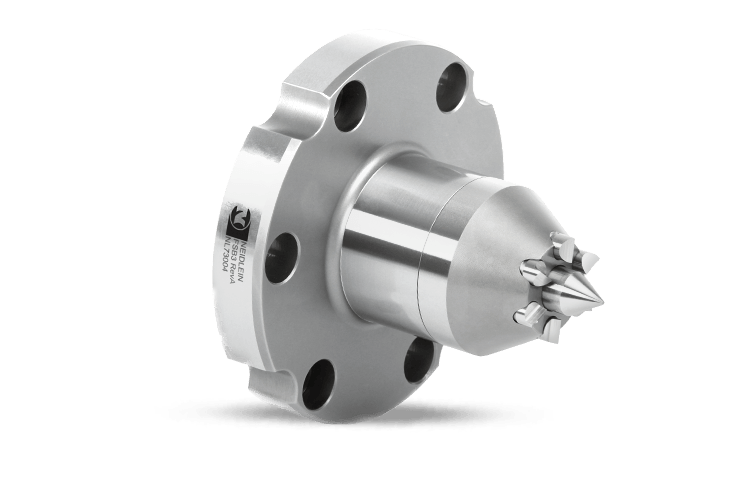

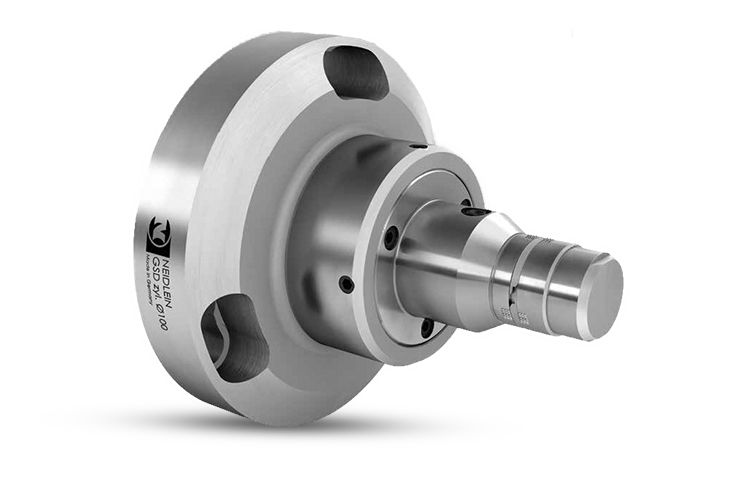

PRODUCTS / Face Drivers

Clamp Shafts between centers to expose the Entire length of the workpiece so you can machine the shaft in a single Application. Operated by the thrust from the Tailstock or Headstock Neidlein mechanical Face Drivers have quick change components with an interlocking mechanism so the Face Driver becomes a solid Driving Fixture with no movement reducing vibration, and Harmonics to help eliminate chatter. This produces maximum torque for deeper cuts, maximum speeds and feeds. Providing a constant Datum-point from the Face or Center hole of your shafts. Which produces High true running Accuracy retaining the center line of the workpiece for the best quality part possible.

Exclusive North American Dealer

- Operated by the thrust from the tailstock

- Mechanical design with internal locking mechanism.

- In locked down position Neidlein’s Face Driver becomes a solid driving fixture with no movement.

- Tighter tolerances are held on workpiece’s.

- Physics – Reduction of vibration, and or Harmonics reduces the chance of chatter.

- Compensating design for workpiece’s with uneven faces.

- Constant datum-point at the face of the workpiece.

- Mechanical construction equates to very little maintenance and customers can repair onsite.

- Drive Pins and Center Points are quick change components.

- Can achieve high speed, and feeds with deep depth of cuts.

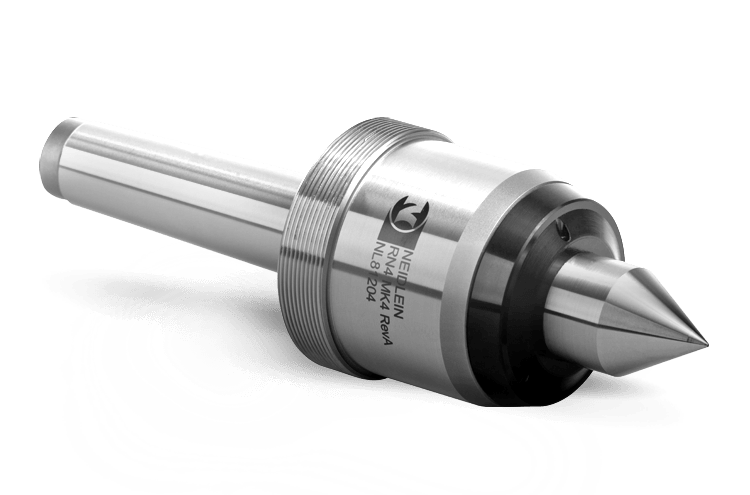

Live Centers

Live Centers

Dead Centers

Dead Centers

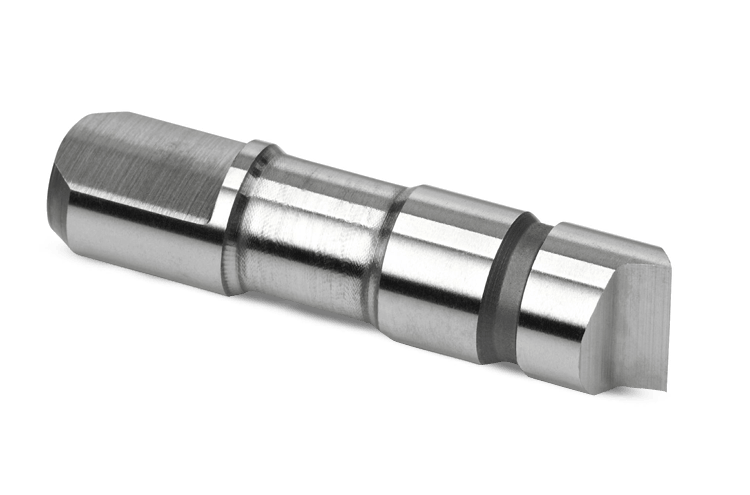

Center Points

Center Points

Drive Pins

Drive Pins

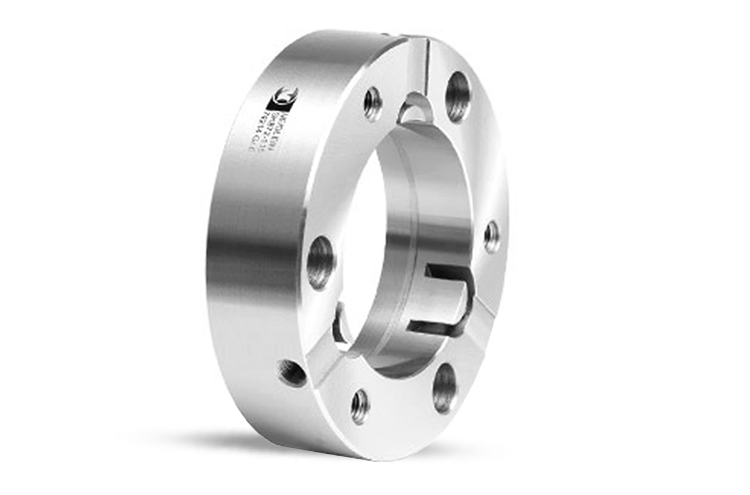

Retaining Elements / Adapters

Retaining Elements / Adapters

Sliding Jaw Mandrel / I.D. Chuck

Sliding Jaw Mandrel / I.D. Chuck

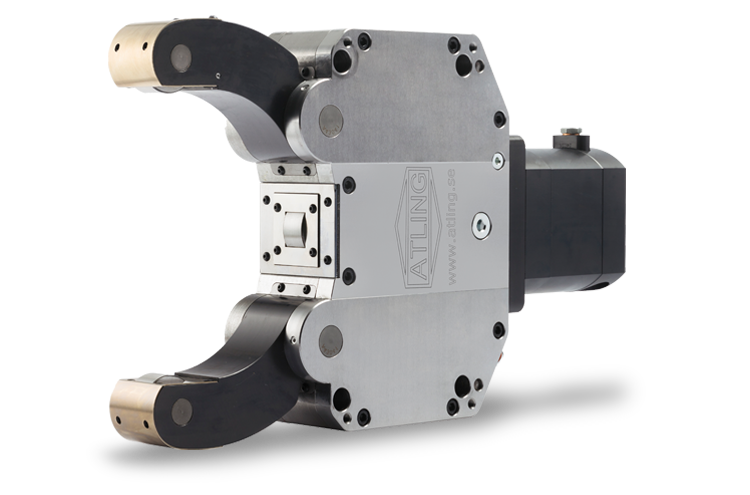

Steady Rest

Steady Rest