News

Face the Facts – Face Drivers are the Way to Go.

All manufacturers want to improve efficiency while maintaining quality. In today’s competitive and volatile world, efficiency just may be the difference between survival and demise. Efficiency is the ability to produce something with a minimum amount of effort. A Face Driver workholding solution will cut your cycle times in half to provide increased production and better quality. So how does a Face Driver work and why is it the way to go?

From a piece of steel held in a lathe or a grinder to the axle in your car, Face Drivers serve a variety of functions. Available in many different sizes depending on the shaft, Face Drivers allow you to tool and finish your piece with just one clamping. Face Drivers clamp shafts between centers to expose the entire length of the workpiece. Face Drivers enable you to machine the shaft in a single application eliminating a second operation. Don’t waste your valuable production time by chucking, un-chucking, flipping, and re-chucking. Face Drivers = Efficiency!

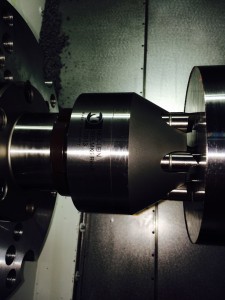

Face Drivers operate by the thrust from the tailstock or headstock. Neidlein Face Drivers have quick change components and are mechanical in design with internal locking mechanisms. In the locked down position, Neidlein’s Face Drivers become a solid driving fixture with no movement; In turn, reducing vibration and harmonics to help eliminate chatter. This produces maximum speeds, feeds, and maximum torque for deeper cuts.

Face Drivers will help streamline your manufacturing process and improve part quality. If you want increased flexibility, lower cycle times, and precision; Face the Facts by going with a Face Driver for you workholding solutions.