Atling steady rest are manufactured in Sweden. Atling has been producing steady rest since 1976 and is one of the world leaders and innovators in steady rest design and manufacturing.

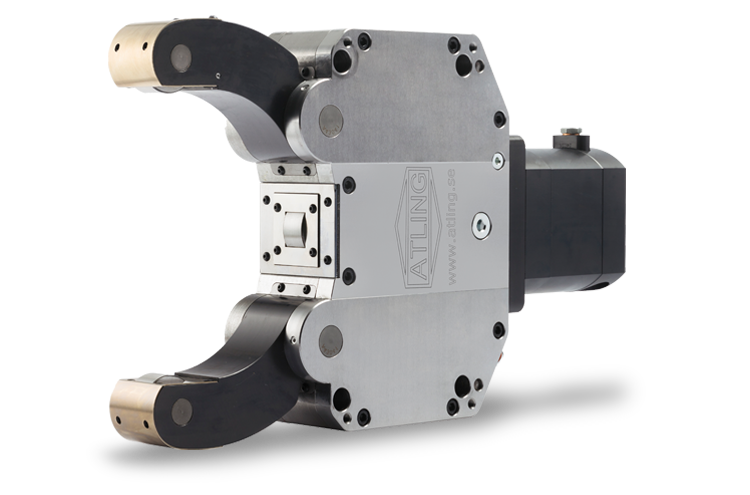

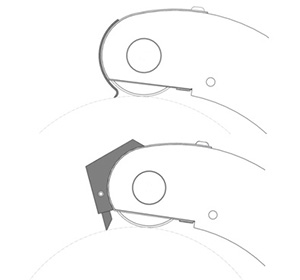

Atling steady rest are manufactured from high strength cast iron with all moveable parts hardened. Atling’s innovated design features allow for a smaller steady rest which enables clamping through a wider range without the need for more space. Another advantage to the Atling steady rest is the capability of being equipped with a swing away system without making the steady rest bigger or the gripping range smaller.

To enhance durability, Atling steady rest are equipped with wipers around the rollers and moving arms to keep out dirt and coolant. There’s also an option to add an overpressure of air internal to the steady rest.

Steady rest are an essential tool when turning long, thin, or heavy shafts and when clamping between the chuck and tailstock does not provide enough clamping force. Steady rest also work great when face drivers which allow the entire shaft to be exposed when turning and machining.

In the machine turning world deflection, chatter, and vibration are the enemy. With the use of a steady rest these are eliminated or reduced resulting in good concentricity and desired surface finishes. Atling steady rest are made to fit all CNC and conventional machines. Mounting is simple, only requiring a fixed bracket which SpinTech Tools can provide or most machine tool manufactures offer.

Exclusive North American Dealer

PRODUCTS

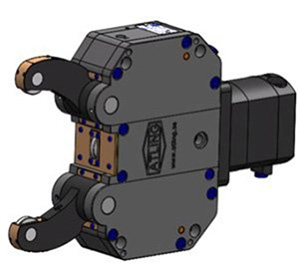

AXE

External Cylinder, Size 1 to 11

AXi

Internal Cylinder, Size 4 to 11

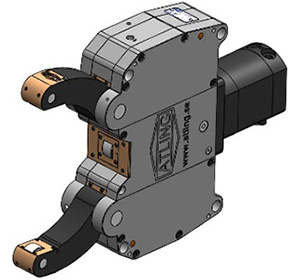

ANE

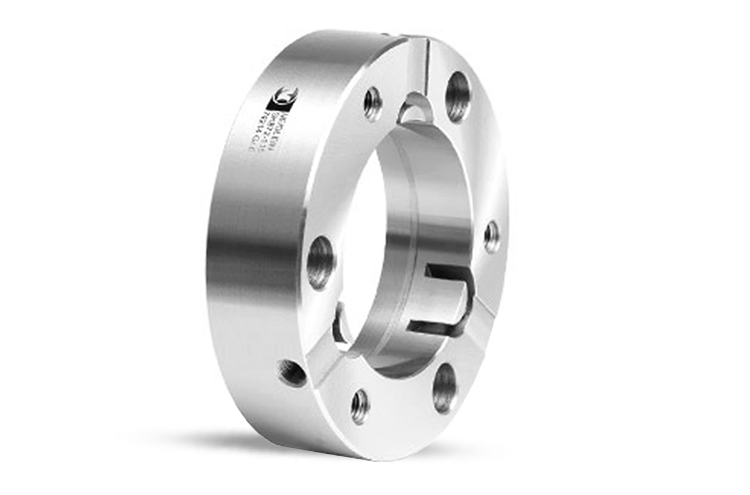

External Cylinder, Narrow Arms, Size 1 to 4

ASE / ASI

External / Internal Cylinder, Size 6 to 8

ACCESSORIES

Bracket

Air Pressure Amplifier

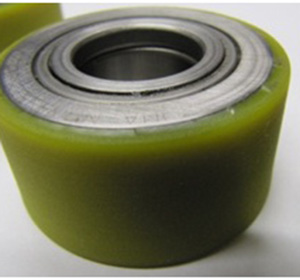

Special Bearings / Diamond shoes

Wipers

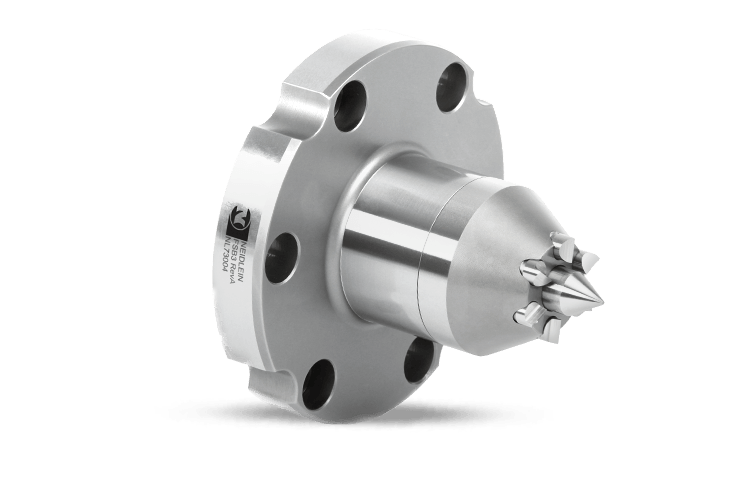

Face Drivers

Face Drivers

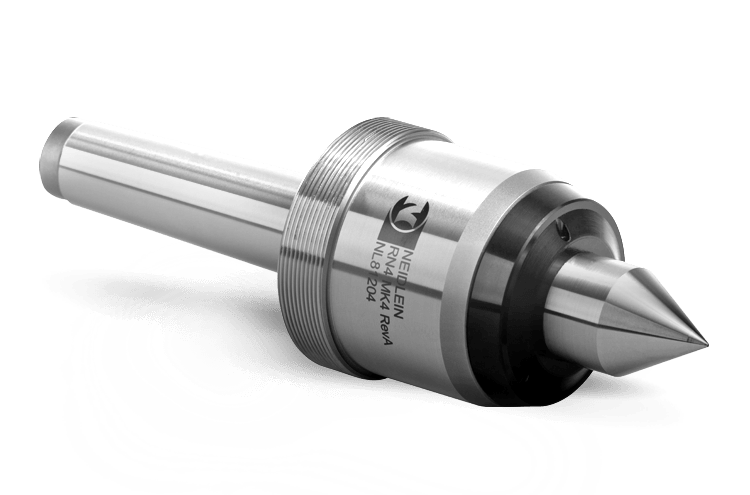

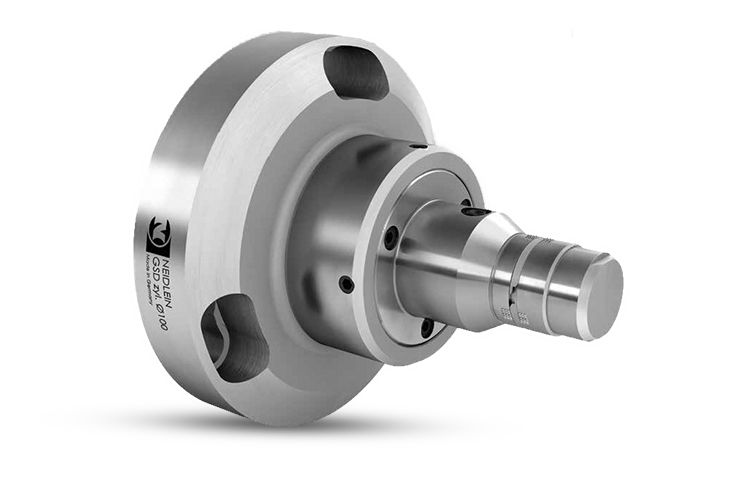

Live Centers

Live Centers

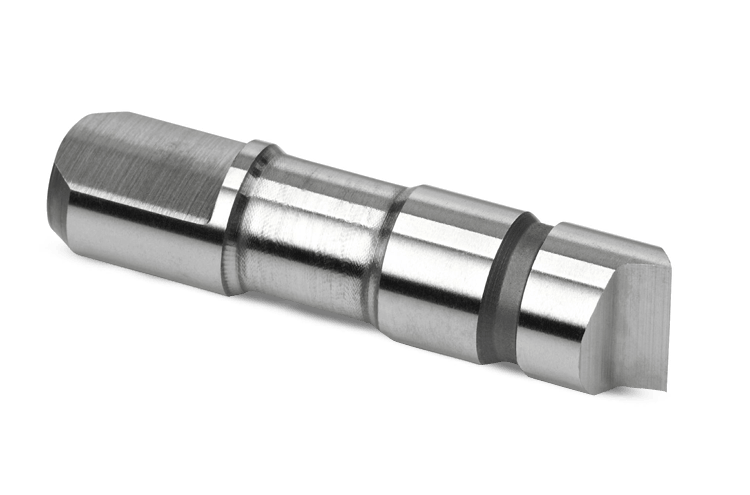

Dead Centers

Dead Centers

Center Points

Center Points

Drive Pins

Drive Pins

Retaining Elements / Adapters

Retaining Elements / Adapters

Sliding Jaw Mandrel / I.D. Chuck

Sliding Jaw Mandrel / I.D. Chuck